Arpel and Ecopetrol conducted a workshop on "Exchange of best practices in H2, hydrocracker and diesel hydroprocesses production units" from October 18th to 20th in Barrancabermeja, Colombia. The workshop culminated with a visit to the important refinery located in the same city.

120 people attended the technical event in person, and more than 150 by virtual means. The workshop aimed primarily at exchanging best practices and lessons learned in the operation, maintenance, inspection, safety and environmental impact of hydrogen, hydrocracker and hydroprocesses production units. It also sought to deepen practices for minimizing emissions, water footprint and impact on the community and workers.

The hydroprocess units play a crucial role in the refineries since they produce both gasoline and diesel free of sulfur and nitrogen, compounds that affect the environment in the combustion process of vehicles.

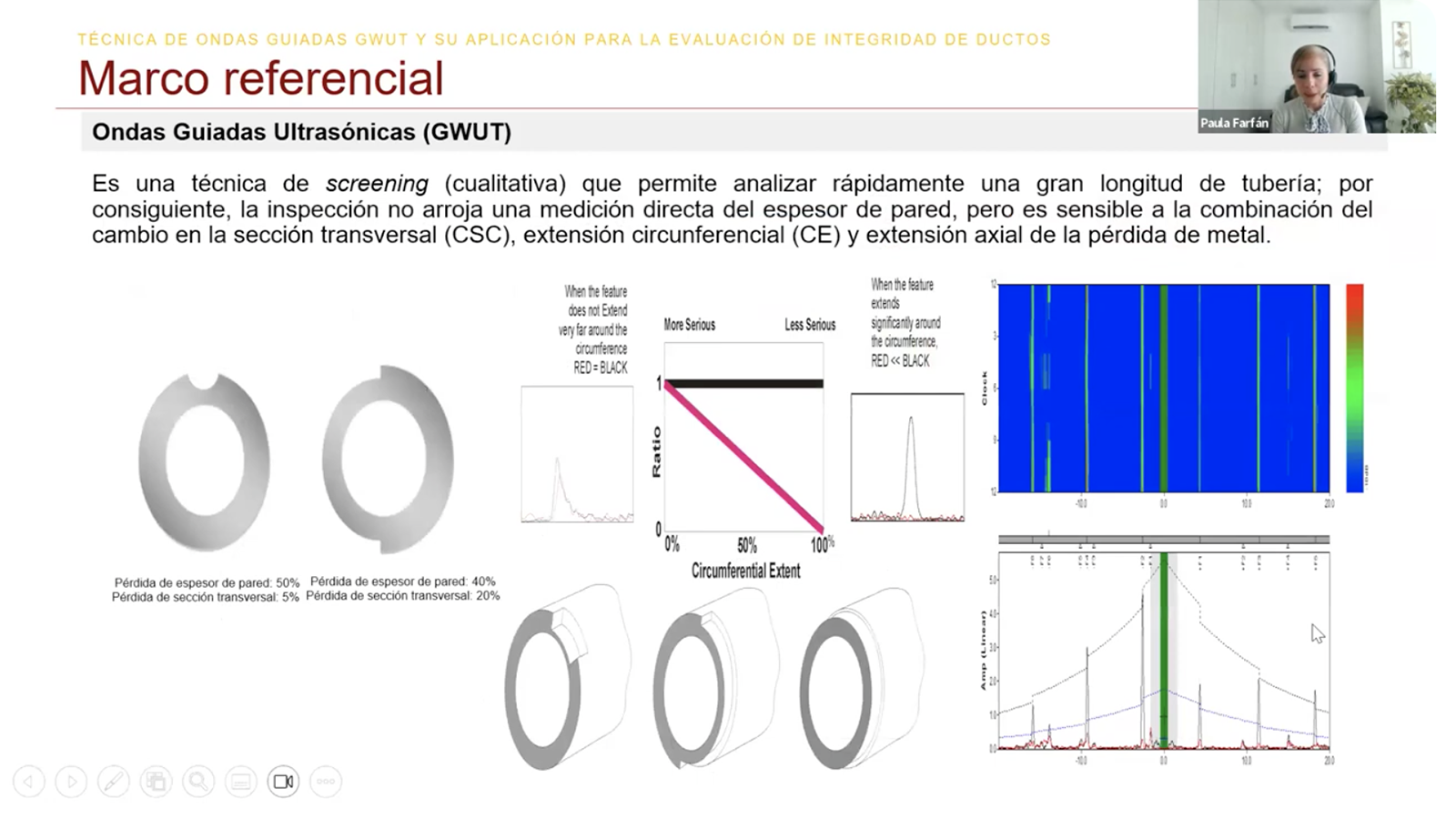

During the event, 24 modules were developed, including presentations and roundtable discussions on: Lessons learned from industrial incidents; New technologies in catalysts; Operations optimization; Best practices in plant shutdowns; Best practices in energy optimization, emissions, etc.; Inspection technologies for static and rotating equipment, and Fuels of the future.

Within the framework of energy transitions, the refining industry in Latin America and the Caribbean faces the challenge of operating its units in an efficient and sustainable manner to ensure the competitiveness and energy security of its countries.

The exchange of best practices and knowledge among professionals from different companies is a factor that helps to achieve this goal and is the mission entrusted to Arpel by its member companies.

Photos:

1st day: https://www.flickr.com/photos/147389427@N08/albums/72177720312357688/with/53301003809

2nd day: https://www.flickr.com/photos/147389427@N08/albums/72177720312358013/

3rd day: https://www.flickr.com/photos/147389427@N08/albums/72177720312342760/with/53301165800